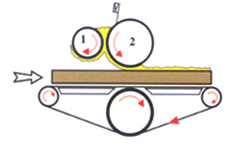

Roller coaters for varnishes

Roller coaters are suitable for coating of all plane surfaces, such as wood panels, metal, glass or rubber.

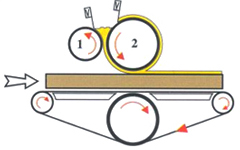

Roller coater mod. TFT/3s. Suitable to apply UV base coats. Spreading amount from 10 to 40 gr/m2

Roller coater mod. TFT/3. Suitable to apply UV base coats and top coats. Spreading amount: Base coats from 10 to 40 gr/m2 - Top coats from 5 to 10 gr/m2

Main features:

- PLC for electronical control.

- Separate motorization of rolls. Single speed regulation by means of inverters.

- Rolls speeds automatic synchronization for cleaning.

- Upper rolls up and down movement are motorized, with emergency device.

- Special reducers + joints for perfect application (without cuts).

- The machine can be extracted from the line on rails.

- Reinforced machine frame.

| Feeding speed | 8-25 m/min |

| Working plane level | 910 +/- 20 mm |

| Useful width | 1300 mm |

| Conveyor belt width | 1300 mm |

| Upper rolls width | 1460 mm |

| Overall dimensions | 1100x2700x1500mm |

| Chrome-plated dosing roll Ø 175 mm | Kw 0,75 |

| Rubberized spreading roll Ø 250 mm | Kw 1,5 |

| Rubberized conveyor roll Ø 240 mm | Kw 1,5 |

| Up/down motor | Kw 0,4 |

| Installed power | Kw 4,5 |

On request it is possible to install a spreading roll with engraved surface "LASER ROLL" able to apply bigger quantity of product (suggested for UV acrilic products, application of 15-50 gr/m2).

Roller coater for varnishes TFT/3/G2

6 indipendent speeds. Two rolls unit for base coats and top coats application (wet on wet system). With motorized blades group. Every rolls unit can be extracted for cleaning.

Spreading amount:

- base coats from 10 to 40 gr/m2

- top coats from 8 to 15 gr/m2

Roller coaters for special applications

Roller coater for application on glass

Roller coater for application on sheet metal (top+bottom sides of the pieces)